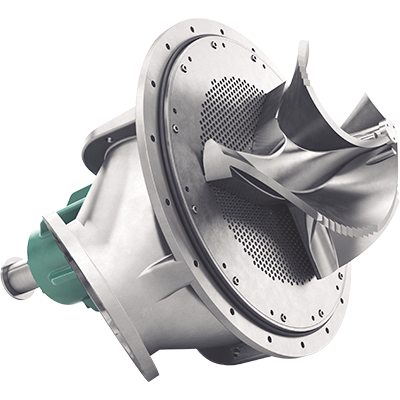

G-rotor

The G-rotor is used for pulp with low dry content, for example in UTM positions such as couch- and press pulpers.

All our rotor units can be used for rebuilding existing pulper vats on site. An upgrade has many benefits: higher capacity, lower service need, and a dramatic decrease in energy consumption.

The G-rotor is used for pulp with low dry content, for example in UTM positions such as couch- and press pulpers.

The S-rotor is equipped with a strainer plate and is used for pulp with high dry content.

The SC-rotor is fitted with counter knives and wear bars for use with wet strength material and other difficult paper qualities.

The SB-rotor simplifies maintenance on UTM pulpers, as the rotor unit can be removed in one piece.

The GRO-rotor is an all-in-one solution including both rotor and pulp outlet. This makes it perfect for rebuilds of existing tubs.

The high consistency rotor is designed for waste paper treatment with operating consistencies between 12–18%.

Test your material in our pilot plant and analyze machine performance in our lab!

Download InfoCustomized designs for your unique application.

Full service on site with your machine delivery.

We have offices in Sweden, Canada, Germany, China, and agents all over the world.

Let us visit your plant and help you improve performance!

Download Info

Are you in need of technical support or wear parts for your machine? Interested in a visit from our staff or a project quotation? Please contact one of our local offices around the world!

Johan Göth

Niklas Tunell

Christian Stiller

Åsa Billfeldt

Gith Cedulf

Stefan Virtanen

Tomas Anarp

Kevin Klassen

Frank Jiang

Kent Xu

Tony Lu

Cellwood Machinery