Pulpers

Energy efficient solutions for paper dissolving Grubbens pulper range offers a high pulping quality, short pulping time, as well as a very low power usage.

The Grubbens product line offers solutions for under-the-machine, bale and broke pulpers, and for high consistencies. Paper mills around the world often operate pulpers of old design which consume significant amounts of energy. Cellwood specializes in rebuilding existing pulpers – a modernization that dramatically can decrease the energy consumption, and also lead to a much higher throughput.

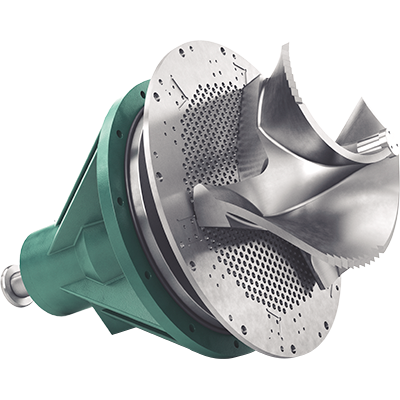

We offer a big variety of rotor units, where each type is designed to give optimal results for a specific paper material: virgin pulp bales, paper machine broke, guillotine broke and wet strength material. With over 2500 installations the efficiency and low power consumption is well proven.

The horizontal pulper design allows for a lower build height as well as a lower energy consumption.

Read moreThe vertical pulper can be run in either batch or continuous operation, and with low, medium or high consistencies.

Read moreAll our rotor units can be used for rebuilding existing pulper vats on site. An upgrade has many benefits: higher capacity, lower service need, and a dramatic decrease in energy consumption.

Read moreApart from pulpers, the Grubbens range also includes reject separators, deflakers, pumps, and high density cleaners.

Read moreTest your material in our pilot plant and analyze machine performance in our lab!

Download InfoCustomized designs for your unique application.

Full service on site with your machine delivery.

We have offices in Sweden, Canada, Germany, China, and agents all over the world.

Let us visit your plant and help you improve performance!

Download Info

Are you in need of technical support or wear parts for your machine? Interested in a visit from our staff or a project quotation? Please contact one of our local offices around the world!

Johan Göth

Niklas Tunell

Christian Stiller

Åsa Billfeldt

Gith Cedulf

Stefan Virtanen

Tomas Anarp

Kevin Klassen

Frank Jiang

Kent Xu

Tony Lu

Cellwood Machinery